Michigan Mine Recovers Silo Capacity And Product.

By Gregg Pickering

There is no perfect design for silos, hoppers or bins. Whether blockages are caused by humidity or inherently adhesive material, buildup on slopes, gates and walls is all but inevitable and capacity is lost. It affects production and raises frustration levels, as recurrent clogging causes unscheduled downtime to address.

Moreover, remediating these issues through methods such as banging on the side of the vessel and jabbing the clogs with tools can pose a safety hazard for staff and lead to equipment damage.

For Lundin Mining, operating the Eagle Mine and the Humboldt Mill in Western Marquette County of Michigan’s Upper Peninsula, workplace safety and a clean, efficient operation are priorities. The staff needed to perform frequent maintenance on storage vessels to dislodge buildup, and as managers recognized the potential hazard and reduced capacity, they sought a solution.

“Due to our stoping method, the raw material can be damp and tacky when it arrives at the mill, so buildup is expected,” said Ted Lakomowski, lead reliability technician for Lundin.

Stoping is a systematic bottom-up method of mining where columns are loosened through blasting then mucked by front loaders into trucks and backfilled using cemented and uncemented rockfill.

“We needed to perform maintenance on the feeder liners located at the bottom of the bin, but we couldn’t do it safely due to the material buildup,” Lakomowski said. “We were concerned solid chunks falling could be a hazard, so we reviewed safe and affordable options.”

From Mine to Silo

Headquartered in Toronto, Ontario, Canada, Lundin Mining is a global company with a focus on the extraction of base metals. As the only primary nickel mine in the United States, the firm’s Eagle Mine produces 1.5% of the world’s total nickel production. It opened in 2014 and is expected to produce 360 million lb. of nickel and 295 million lb. of copper, as well as small amounts of other metals over its estimated 11-year lifespan.

The company uses a bench-and-fill stoping process to extract roughly 2,200 short tons per day (2,000 metric tons per day), hauled to the surface by specialized underground trucks. The haulers carry approximately 100,000 lb. (45,400 kg) loads through a 1 mile (1.6 kg) long and 18 ft. (5.4 meters) diameter ramp shaft descending into the earth at a 13% grade.

Raw ore is first stored in a covered stockpile facility prior to transport 65 miles (105 km) by truck to the Humboldt Mill. Upon arrival, the raw ore is passed through a series of crushing and conveying circuits, reducing it to 3/8 in. (9.5 mm) in size. Material is then conveyed by a series of 30-in. (76 cm) wide conveyors traveling at 300 ft.-per-min. (91.4 meters-per-min.) from the crushing circuit to the fine ore bins.

The three rectangular bins, each with a capacity of approximately 45,000 cu. ft. (1,274 cu. meters), are arranged side by side, tapering down to six slot feeders on the bottom (two in each bin). The mouth of each bin is supported above by a structural steel beam divider.

The stored material then enters a single stage ball mill which grinds it further to the consistency of sand, where it is mixed into a slurry and passed to a selective flotation process to separate the nickel and other valuable minerals.

Silo Cleaning Safety

Located inside a processing complex, the moisture content of the material passing through the three rectangular fine ore bins ranges from 1% to 3%, depending on the time of year. “Over the span of three years, a considerable amount of oxidized ore began to form on the walls of the bins,” Lakomowski explained. “The buildup began forming ratholes, and random chunks would break free from the bin wall at times and plug the feeder below. Unblocking the feeder is a manual effort that could be hazardous, so we wanted to mitigate the risks.”

Roughly 30 ft. (9 meters) tall, each bin has two discharge feeders at the bottom, separated by a pant leg divider discharging onto the feeder belt. Lakomowski estimated that they were losing approximately 15% to 20% capacity of each bin from adhered material.

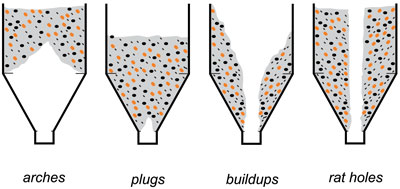

Rat holes generally form in the center of hoppers, bins and silos as a result of buildup around the sides. Although the accumulation did not completely obstruct the flow of material, it quickly diminished the capacity of the vessel and often led to “bridging,” a complete blockage that brought the process to a stop.

The accumulation could fall in chunks at any time, even without intentional disruption, making it hazardous to workers during maintenance activities. Once material dislodges and feeder lines get blocked, workers must reach in with tools to break apart the obstruction, a hazardous procedure that the company deemed unsustainable.

Heavy accumulation can also cause weight distribution issues. It is well known that flowing bulk materials can create unequal wall pressures on silos.[1] If left for too long, the buildup can increase the hazards of wall damage. Storage vessels are typically constructed of a sturdy metal frame, with walls consisting of one or more relatively thin metal sheets. To react to pressure differences of filling and unloading the silo, some flexibility is advantageous. However, excess weight – especially when unevenly distributed and coupled with pressure buildup – can cause expensive structural damage.

Air Flail Cleaning

To avoid injuries, downtime and equipment damage associated with silo buildup, operators contacted a cleaning contractor. Although the material had hardened, it consisted of fine particulates, so the contractor used an air pressure system with a flail head to break the accumulation loose. The attachment had thrashing hoses that discharged a powerful stream of compressed air through the central rathole shaft.

The silo has internal support beams that maintain the structural integrity of the vessel. Due to the erratic nature of the flailing arms, contractors struggled to prevent them from wrapping around and tying up in the beams. This would cause a work stoppage to disentangle the arms, extending the schedule and leaving the support crew standing idle. Frustrated by time constraints and increased costs, management decided to contact Martin Engineering about alternative silo cleaning methods that might better accommodate the structural constraints of the bin.

Whip Cleaning

“The compressed air approach was somewhat effective, but the device kept getting hung up on the beams inside the bin,” said Martin Engineering Territory Manager Jason Haynes. “The flail attachment shoots pressurized air over a wide area,” he explained. “Although it might work in some open silos, in this case, it wasn’t the right tool.

“When they brought the issue to our attention, we examined the vessels and reviewed the options for a viable solution,” Haynes recalled. “Fortunately, the material was non-combustible and each bin had two access points, so we had choices for the specific system to use. Due to the dense solidification, we decided to go with the heavy-duty whip.”

An experienced two-man crew set up two Martin HD (heavy-duty) Whip Busters at the top of the bins, outside of the access hatches. Powered by compressed air, the system can be equipped with a variety of whips, flails and cutting edges for specific materials and applications. Each attachment is designed to knock down accumulated material without damaging the vessel walls or support structure.

If the material is completely blocking the discharge, the crew will typically use a “bin drill” to open a 12-in. (305-mm) diameter hole through the accumulation. The drill’s powerful hydraulic action drives its way through blockages, clearing a pathway at depths up to 45 meters (150 ft.) This becomes the channel for the loosened material to flow through, and the silo cleaning crew then uses the bin whip to finish the cleaning.

Able to extend as far as 28 ft. (8.5 meters), the coiled modular boom can clean vessels as wide as 60 ft. (18 meters) in diameter and 225 ft. (68.5 meters) tall.

Lowered into the silo from the access hatch, the device operates from the bottom up as the pneumatic cutting head delivers a powerful whipping action to dislodge even difficult materials. The extending arm and remote operation provide operators control over the whip head, allowing the team to completely clear dense material with no hang-ups on support bars and no confined space entry required to untie tangled equipment.

At the bottom of the bin, a six-person crew broke apart large chunks using various tools, adding it back onto the conveyor for a pass through the ball mill and then on to processing. Due to time lost from the previous unsuccessful silo cleaning activities, three shifts were set up for 24-hour operation to minimize the additional disruption. “Production constraints forced us to clean each bin a few weeks apart from one another,” said Lakomowski. “Thankfully, Martin was able to work around our schedule.”

Site Safety

After accumulating for three years, the buildup had hardened significantly. Operators knew that the impact from the whip would cause cracks that could allow large pieces to fall out of the discharge, possibly creating hazardous debris upon impact. This required some extra precautions to be taken.

Safety measures included:

- Blocking the access holes with a hard barricade and red danger tape on the top of the bins.

- At the bottom, caution tape around the debris dispersal area.

- The feeder belt was shut down and the lock-out/tag-out procedure was completed before any material removal.

- Trained personnel operating the silo cleaning machinery.

- Safe procedures for breaking up large debris.

- Keeping the area clean and free of debris during the project.

Increased Capacity Improves Production

After the cleanouts were completed, operators reported that the bins are at 100% capacity and production has become more efficient as a result. The stringent 24-hour cleanout schedule reduced the timespan for the project, minimizing operational downtime and improving the return on investment (ROI).

Safety protocols were strictly followed and the area is now safer to work around. “In our experience, Martin was the safest and most cost-effective option,” Lakomowski remarked. “By targeting the problem areas in a controlled manner, we were able to maintain our production operation without any significant disruptions.”

Gregg Pickering is a silo services technician for Martin Engineering.

References

[1] Swinderman, Todd; Marti, Andrew; Goldbeck, Larry; Marshall, Daniel; Strebel, Mark: Foundations — The Practical Resource for Cleaner, Safer, More Productive Dust & Material Control; Fourth Edition; pg. 408; Martin Engineering; Worzalla Publishing Company; Stevens Point, Wisconsin 2009. https://www.martin-eng.com/content/page/552/foundations-conveyor-systems-book